- PRODUCTS

- Product Index

- Product Index

- New & Featured Instruments

- By Test Standard

- ISO Standards

- ASTM Standards

- TAPPI Standards

- Other Standards

- Testing Software

- Datashield

-

SOLUTIONS

- Classified by packaging materials

- Bag packaging

- Bottle / barrel container

- Carton Packaging

- Packaging Solutions

- Bag packaging

- Bottle/barrel container

- Carton

- Fine Chemicals

- Fine Chemicals

- Medical device Solutions

- Medical device packaging

- Special medical equipment

- Solutions for Researching Institutes

- Solutions for Researching Institutes

- Solutions for Inspection Institutions

- Solutions for Inspection Institutions

- TESTING SERVICES

- NEWS & EVENTS

- ABOUT US

- CONTACT US

- ADD FAVORITES

- LANGUAGE

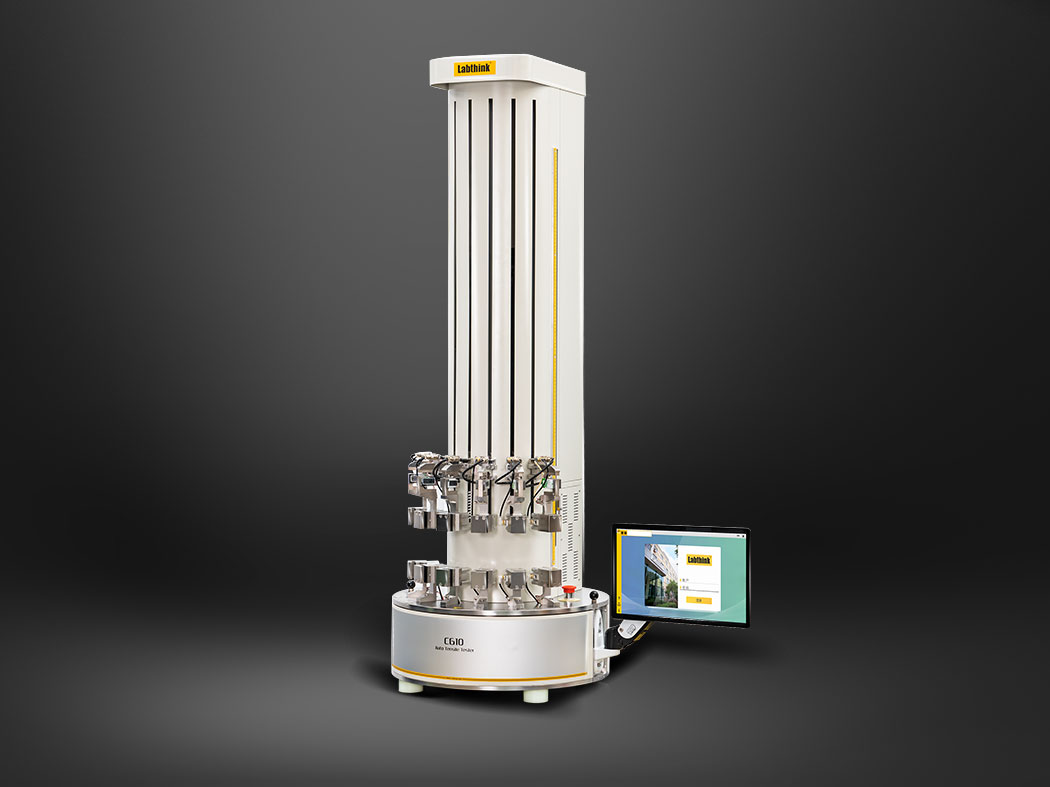

C610G Auto Tensile Tester

C610 GAuto Tensile Tester is suitable for testing the tensile strength, peeling,elongation, tearing, heat sealing, adhesion, puncture force, opening force,low-speed unwinding force, and pull-out force of products including plasticfilms, composite materials, flexible packaging materials, plastic pipes,adhesives, adhesive tapes, self-adhesive labels, medical patches, releasepaper, protective films, combined aluminum/plastic caps, metal foils,diaphragms, backsheet materials, non-woven fabrics, rubber and paper, etc.

Product FeaturesNote 1

Precise and Efficient

Powerful Functionality

IntelligentControl

Test Principle

The specimen is clamped on the grips between the center crossbeam and the base. The center crossbeam and base move relative to each other. A load cell located on the center crossbeam and a displacement sensor built into the tester collect force and displacement changes during testing, allowing calculation of various mechanical performance indicators.

Reference Standards

ISO 37, ASTM E4, ASTM D882, ASTM D1938, ASTM F88,ASTM F904, JIS P8113

GB 8808, GB/T 1040.1-2006, GB/T 1040.2-2006, GB/T1040.3-2006, GB/T 1040.4-2006, GB/T 1040.5-2008, GB/T 4850-2002, GB/T12914-2008, GB/T 17200, GB/T 16578.1-2008, GB/T 7122, GB/T 2790, GB/T 2791,GB/T 2792, GB 14232.1-2004, GB 15811-2001, GB/T 1962.1-2001, GB 2637-1995, GB15810-2001, QB/T 2358, QB/T 1130

YBB00042005, YBB00112004

Applications

The C610series of Auto Tensile Testers offer a wide range of applications, with over100 different specimen grips available for users to choose from, satisfying thetesting requirements of over 1,000 materials. Labthink also providescustomization service to meet diverse testing needs for different materials.

Examplesof some applications are as follows:

Basic Applications | Extended Applications (are to be realized with specific accessories or customization) | |||

Tensile Strength and Elongation Rate | Ampoule Breaking Force | Film Puncture Force | Puncture Force of IV Bag Caps with Bags | Puncture/pull-out Force of Soft Rubber Stoppers |

Tensile Strength at Break | Opening Force of Combined Aluminum/plastic Caps | Tearing Force of ZD-type Caps | Opening Force of Oral Liquid Caps | Puncture/pull-out Force of Oral Liquid Caps |

Heatseal Strength | 90-degree Pull-out Force of IV Bag Caps | Pull-out Force of IV Bag Caps with Bags | 23-degree Pull-out Force of Bottle Caps | Puncture/pull-out Force of Bottle Caps and Rubber Stoppers with Bottles |

Tear Resistance | 90-degree Peeling Force of Adhesive Tapes | Tear Resistance of Adhesive Binding Books | 90-degree Peeling Force of Water Insoluble Plasters | Tearing Force of Adhesives |

180-degree Peeling | Adhesive Strength Test (Soft) | Adhesive Strength Test (Hard) | Peeling Force of Flexible Tube Caps | Disengagement Force of Catheter and Connector |

90-degree Peeling | Pull-out Force of Cosmetic Brush Hair | Pull-out Force of Toothbrush Hair | Breaking Force of Ropes | Opening Force of Jelly Cups and Yogurt Cups |

Tensile Strength at Defined Elongation | Peeling Force of Milk Cup Films | Pull-out Force of Rubber Stoppers | 45-degree Peeling Force of Bottle Films | Tensile Strength of Ziplock Bag Mouths |

| Peeling Force of Magnetic Card Cores | 90-degree Peeling Force of Magnetic Cards | Tearing Force of Heat Sealing Films | Separating Force of Protection Films |

| Separating Force of Release Paper | Trouser-type Tearing Force | Unwinding Force of Adhesive Tapes | Pressure Resistance of Plastic Bottles |

| 20-degree Bevel Peeling Force | 135-degree Peeling Force of Plugs | Floating Roller Peeling Grips | Eccentric Grips |

| Grips for Wide Specimens | Japanese-style Sample Grips | British-style Sample Grips | Breaking Force of Contact Lens |

| Pressure Resistance of Jelly Cups | Compression Resistance of Packages | Compression Resistance of Sponge | Puncture Resistance of Simulated Skin |

Technical Parameters

Table1: Test Parameters Note 2

Parameter/Model | C610G | |

Loadcell Specification | N | 500 |

50, 100, 250 (optional) | ||

Resolution | N | 0.001 |

Accuracy | N | ±0.5% of indication (2%FS~100%FS) |

±0.01%FS (0%FS~ 2%FS) | ||

Test Speed | mm/min | 0~500 (can be set as any integer) |

Speed Accuracy | mm/min | Indication ± 0.5% |

Extended Functions | 21 CFR Part11 | Optional |

GMP computer system requirements | Optional | |

Table2: Technical Specifications

Number of Test Stations | 6 |

Speicimen Width | ≤ 30 mm |

Specimen Thickness | ≤ 3mm |

Clamping Method | Pneumatic |

Gas Specifications | Compressed air (gas source is to be prepared by the user) |

Gas Source Pressure | ≥ 72.5 PSI / 500 kPa |

Port Size | Φ 4 mm polyurethane tube |

Dimensions | 66.1” H x 22.8” W x 22.8”D (168cm× 58cm×58cm) |

Power | 120VAC±10% 60Hz / 220VAC±10% 50Hz (select one from the two) |

Net Weight | 440Lbs (200kg) |

Table3: Product Configuration

Standard Configuration | Instrument, Software, Loadcells (6 pieces), Pneumatic Grips (12 sets), Φ4mm Polyurethane Tube |

Optionals | Industrial Touch Computer, PC, GMP Computer Systems Requirements, 21 CFR Part11, Printers Air Compressor, Sample Cutter, Test Plate, Standard Roller |

Note 1: The product featuresmentioned above are subject to the specific annotation in the "TechnicalParameters" table.

Note 2: The parameters in the tables are measuredby professional operators in Labthink laboratory according to the requirementsand conditions of relevant laboratory environmental standards.

Labthink is committed to the innovationand improvement of product performance and functions. For this reason, thetechnical specifications of the products may be changed accordingly. Thecompany reserves the right to modify and interpret the above without priornotice.

We can help you select or customize the proper unit for your test requirements.

Related Products

Product Categories

Search Products

Need help or have a question? For more information on how Labthink can help your company profit through testing, please Click the button.