Stacking bag breakmeans that the food packaging should be able to withstand a certain stackingforce during transportation and storage, otherwise the food packaging will bebroken. Sealing crack generally refers to lax sealing, packaging opening, bottlemouth seepage, bottle mouth leakage, and plastic bottle mouth bursting. Packagingof substandard quality will cause the above issues:

1) Inferior physicaland mechanical properties - such as packaging materials are weak to punctures;or tearing and piercing during the storage, transportation and selling. If thedamages were not discovered in time, the food would be exposed to a largeamount of oxygen which may lead to oxidation and deterioration. If the packagingmaterial is the weak to low temperature, when it is subject to coldenvironment, the original physical and mechanical properties will be diminished,and brittle rupture may occur.

2) Poor sealing strengthat the sealing site – when the heat sealing strength of the flexible packagingmaterial is too large, the package is easy to crack at the bottom of the sealingsite; when the heat sealing strength is too low, it will cause the sealing tocrack; if the torque of the bottle cap is not appropriate, and the bottle mouthis likely to leak.

C670M Falling Dart Impact Tester

C670M Falling Dart Impact Tester is designed to measure the impact resistance of plastic films in compliance with ASTM D1709.

C610H Auto Tensile Tester

C610H , also tensile strength Tester is professionally used for tensile testing, seal strength testing, and etc for flexible materials. This tensile tester has high resolution and accracy.

C630H Heat Seal Tester

C630H Heat Seal Tester is applied in measuring heatsealability of a surface, or sealant layer a packing material under controlled temperature, pressure and time conditions.

C632B Hot Tack Tester

C632B Hot Tack Tester is to determine hot tack seal strength tests of packaging films according to ASTM F1921.

FIT-01 Film Pendulum Impact Tester

FIT-01 can be used to determine impact resistance properties of pendulum of plastic films, sheets, composite films, aluminum foils and other materials in accordance with ASTM D3420.

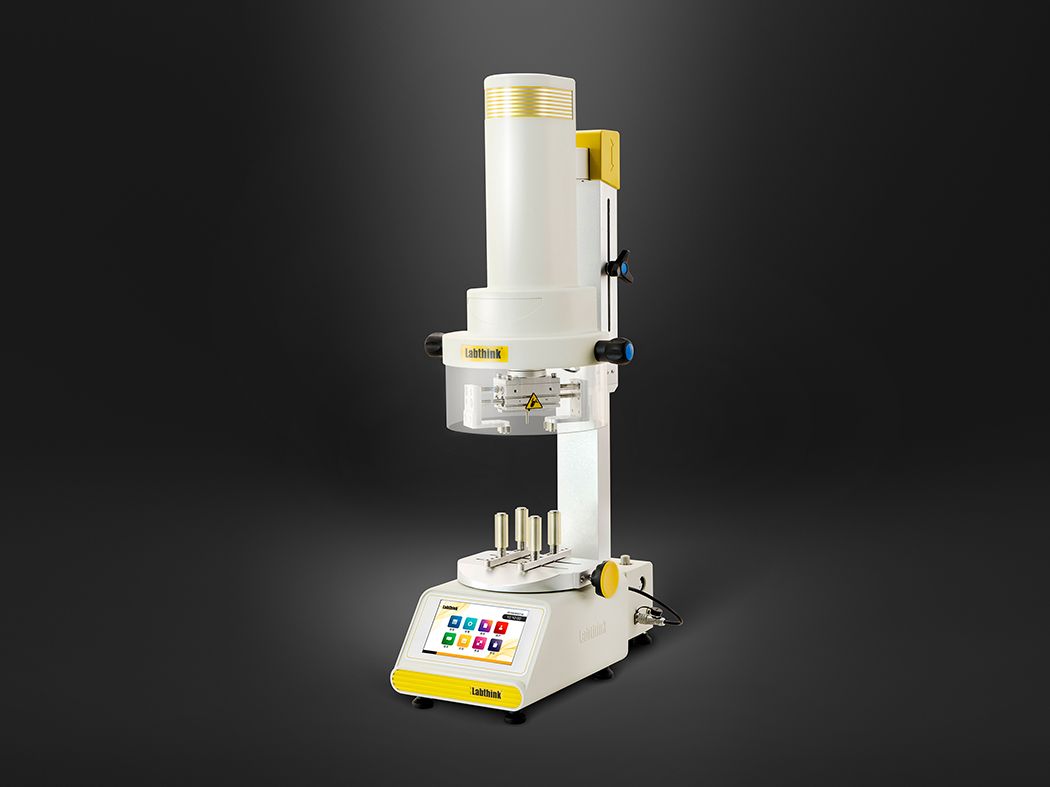

C612M Automatic Bottle Cap Torque Tester

C612M Digital Torque Tester is the first generation of automatic torque tester with manipulator to measure the application torque and removal torque of the caps of bottles, spout bags and flexible tube packages.

C660M Leak and Seal Strength Tester

C660M Leak and Seal Strength Tester can used for leak test, burst test and creep test of finished packages and three-side sealed packages, based on ISO 11067, ASTM F1140 & ASTM F2054.

C660B Leak and Seal Strength Tester

C660B, also vacuum leak tester is based on ASTM D3078. Using bubble emission method, the vaccum Leak Tester can be used for gross leak test of various packages and bottles.

C611M Box Compression Tester

C611M Box Compression Tester can be used to measure the compressive resistance, deformation and stacking capability of corrugated cartons and box packages.

C681M Flex Durability Tester

C681M Flex Durability Tester (Gelbo Flex Tester) is professionally applicable to the determination of flex durability of flexible films, composite films and coating films.